[hfe_template id=’30’]

SLEEVE

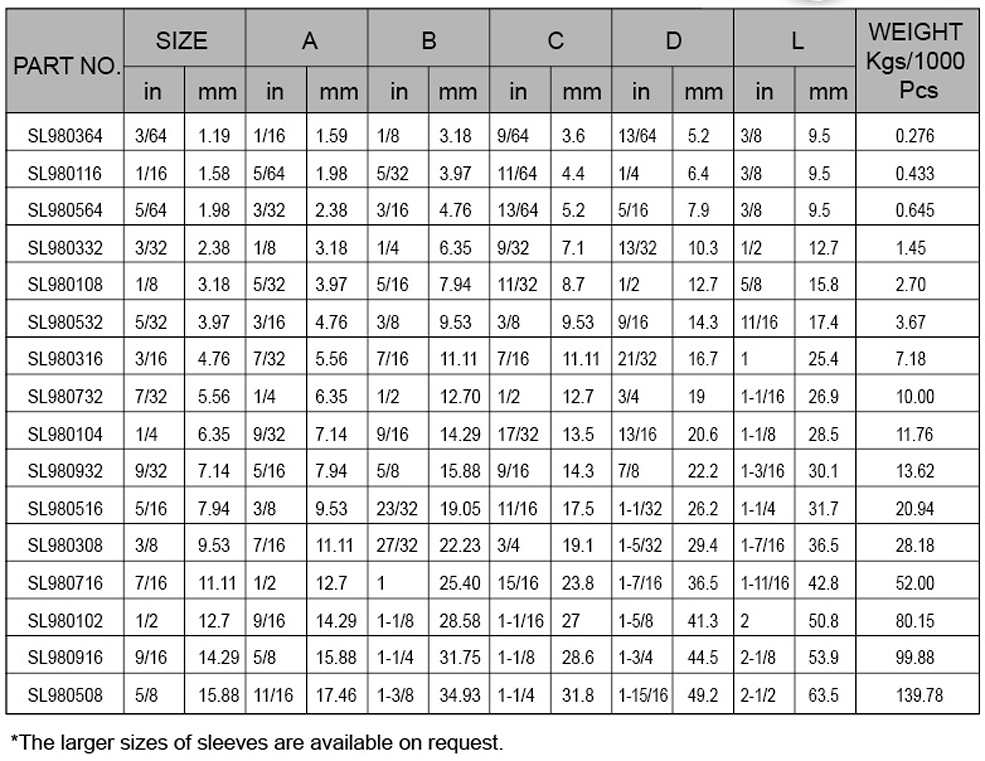

Aluminium Sleeve

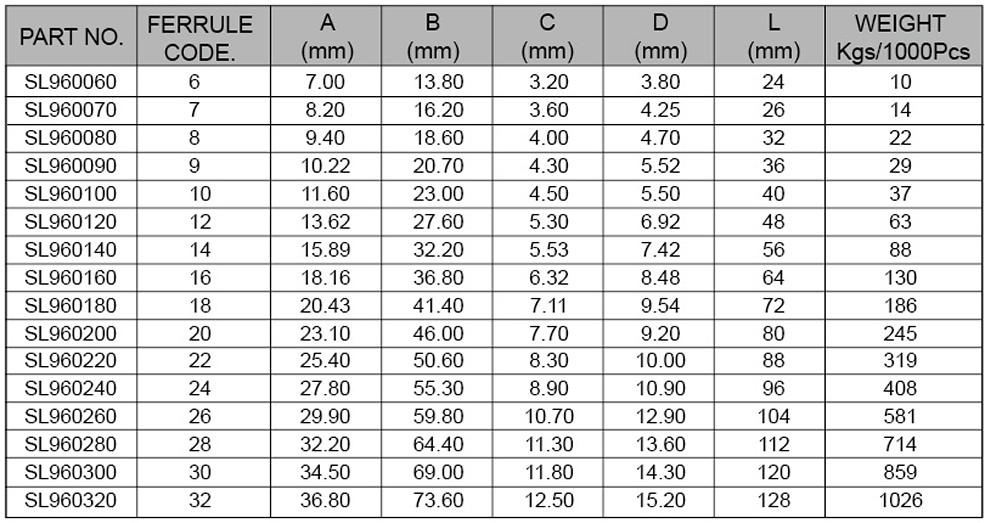

Aluminium Ferrules Form C

Aluminium Hourglass Sleeves

Aluminium Oval Sleeves

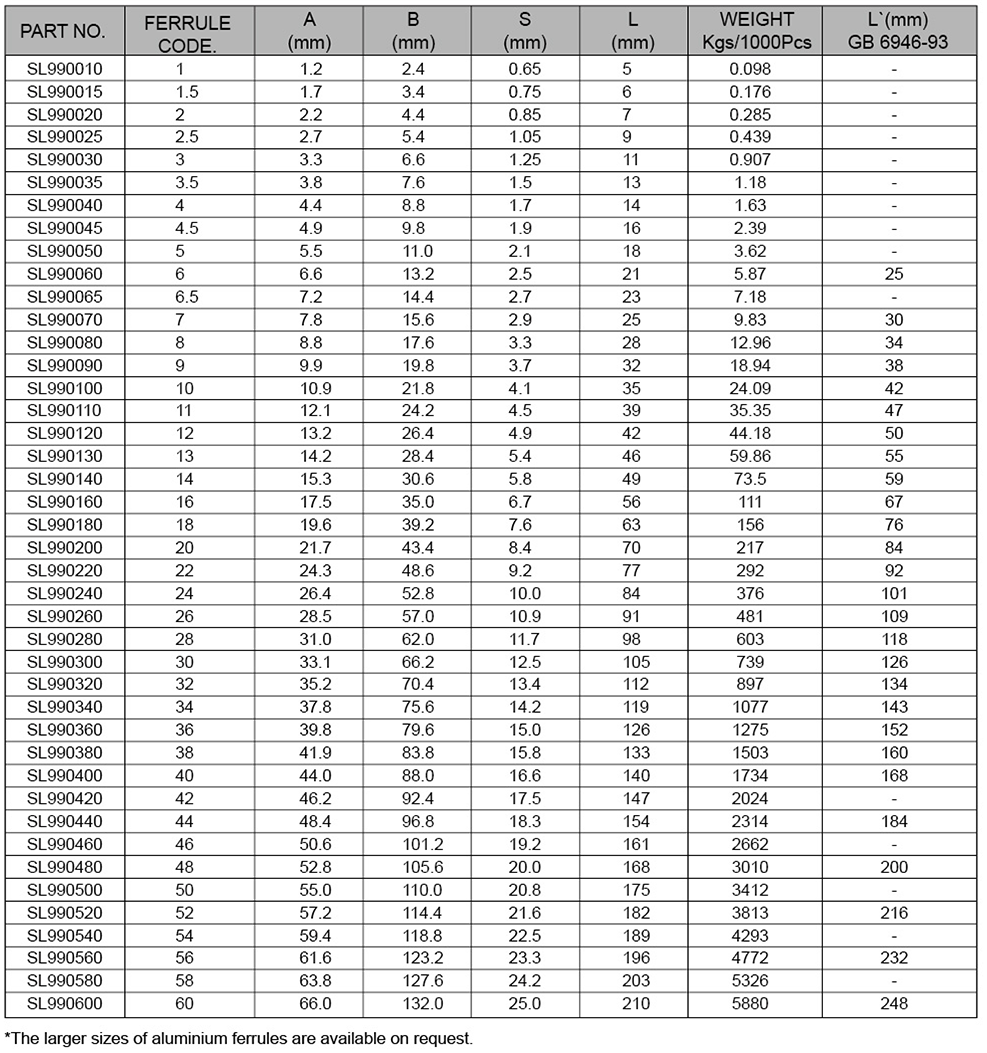

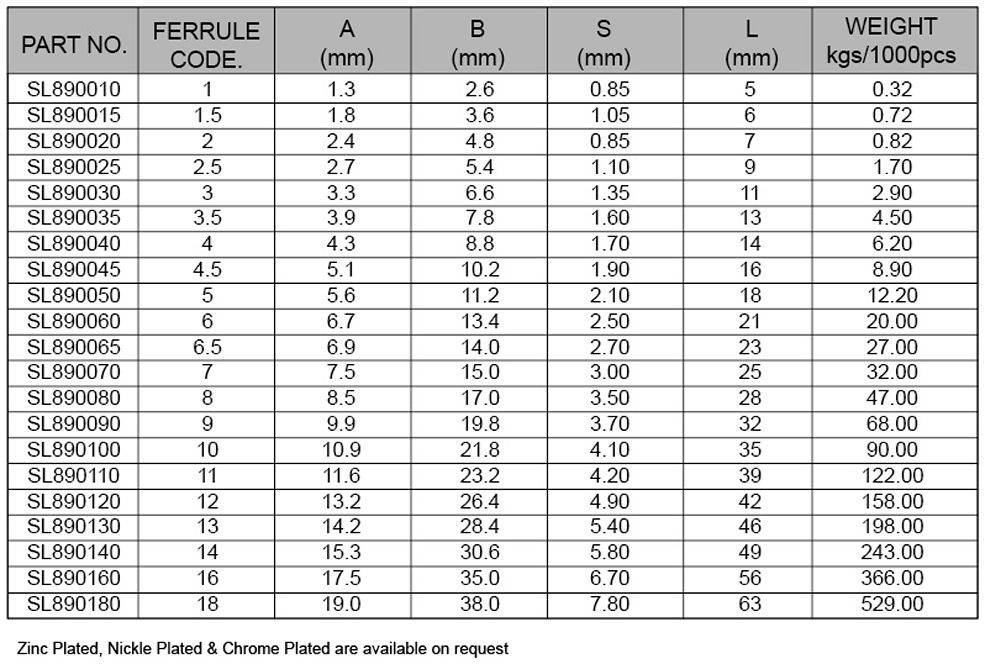

Aluminium Ferrules Specification EN 13411-3 (DIN3093)

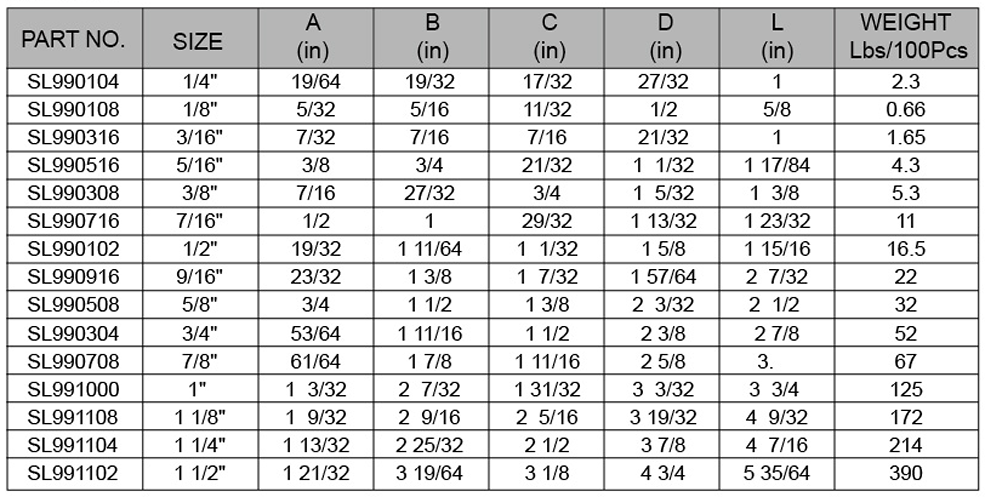

Aluminium Ferrules JIS Type

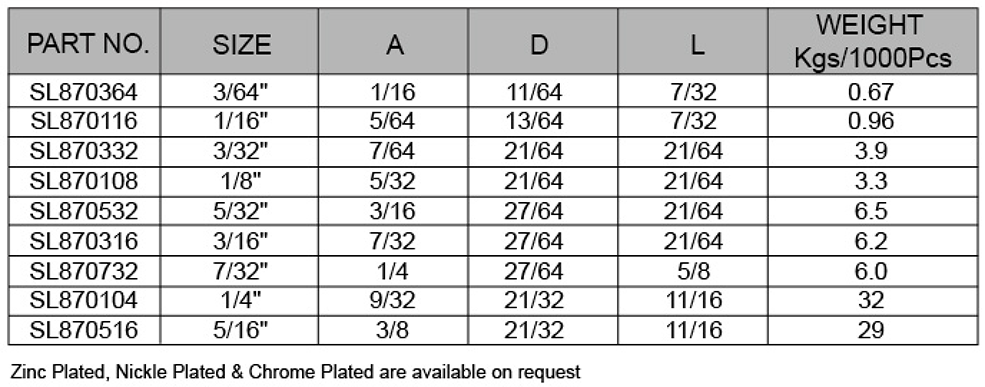

Aluminium Stop Buttons

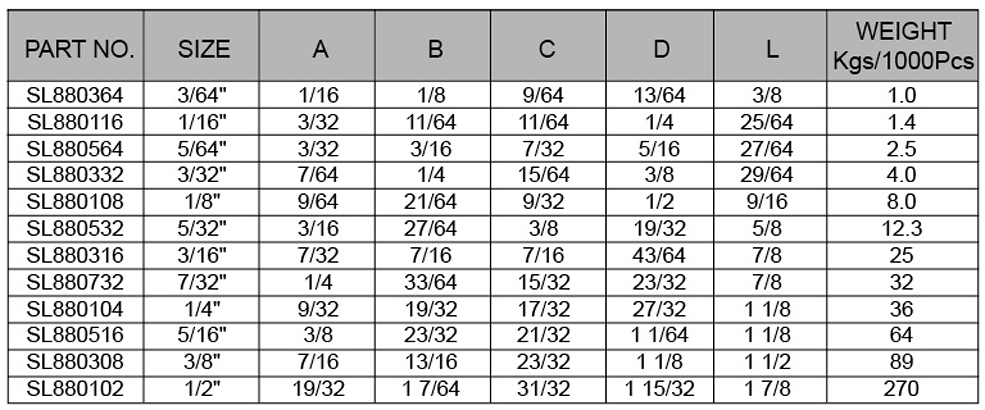

Copper Sleeve

Copper Button Stops

Copper Hourglass Sleeves

Copper Ferrules

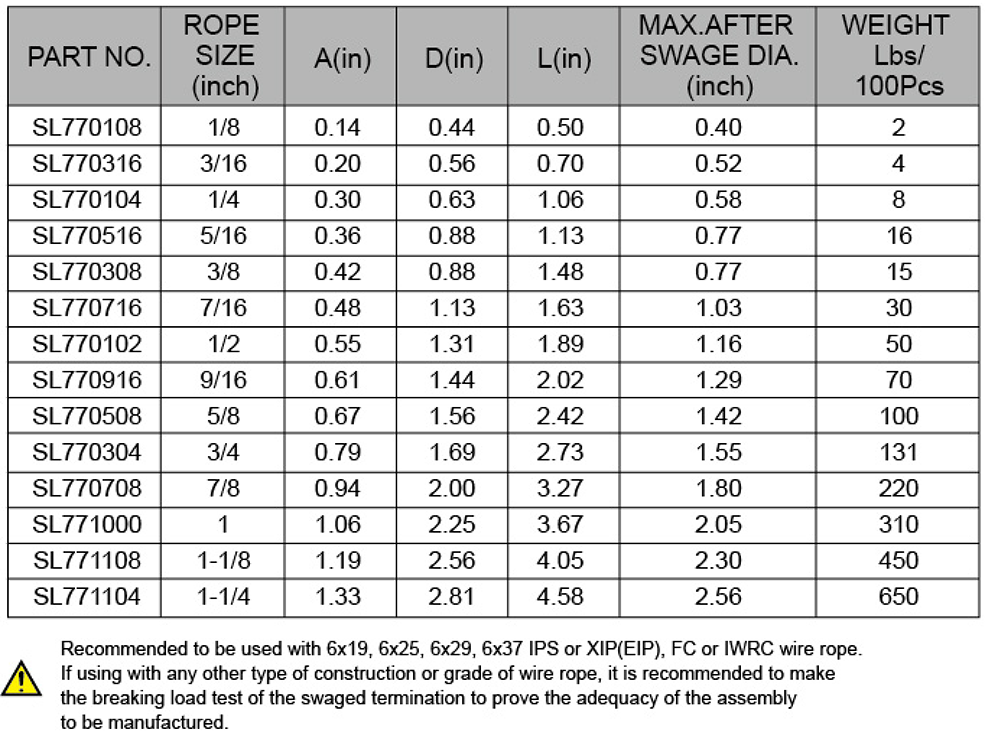

Steel Sleeve

Steel Stop Buttons

Steel Oval Sleeves

Flemish Eye Steel Swaging Sleeves (S-505)

Forged open swage terminals

Forged closed swage terminals

Grooved Open Spelter Sockets

Grooved Closed Spelter Sockets

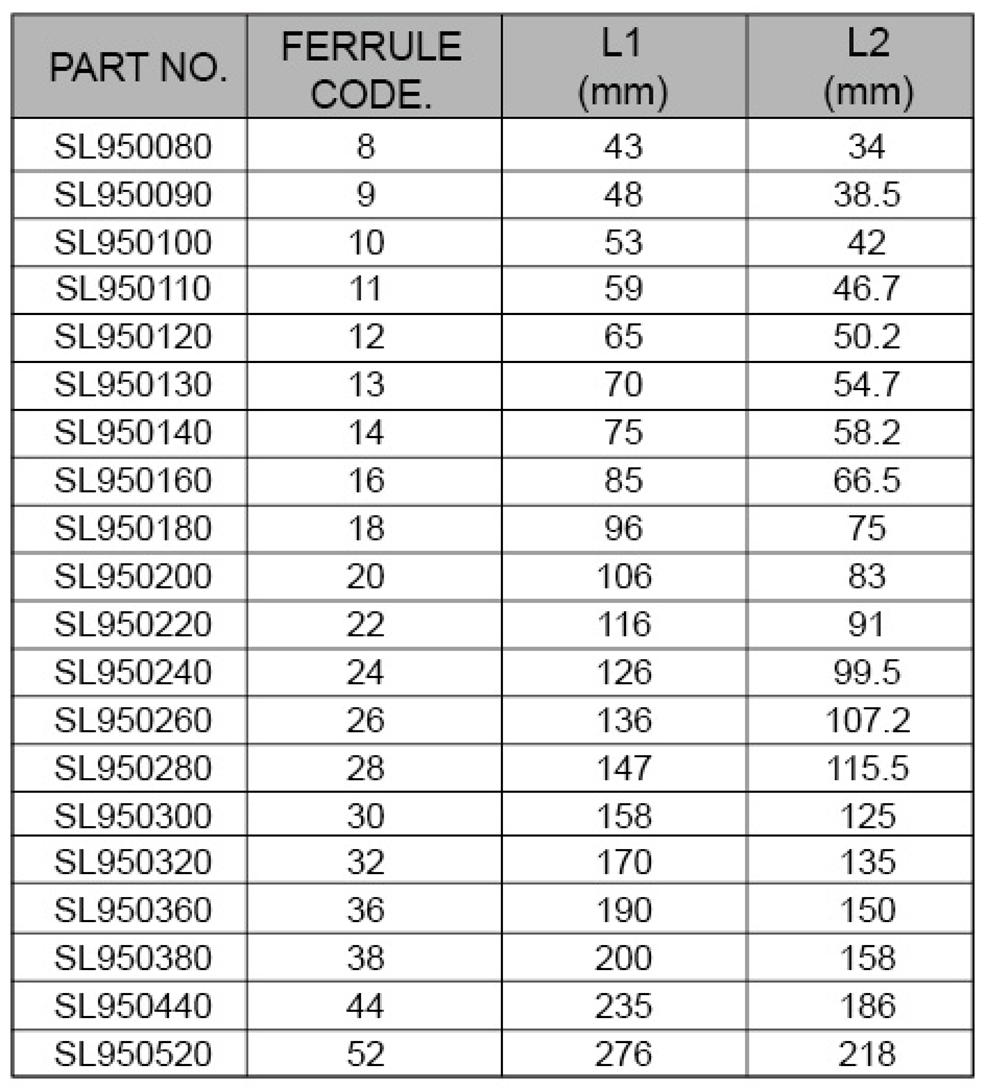

Table Parameters

Aluminium Ferrules Form C

The inspection hole guarantees control of the correct inserted length of wire rope before and after swaging.

These types of sleeves have to be swaged with the conical type C swaging dies.

Solicita tu cotizacion aqui

Aluminium Hourglass Sleeves

Solicita tu cotizacion aqui

Aluminium Oval Sleeves

H-quality aluminum oval sleeves are extruded from a high quality aluminium alloy,and heat treated for excellent cold forming or swaging qualities.

Return eye splice using ALUMINIUM SLEEVES will attain 95% of Improved plow wire rope catalog strength when properly swaged.

CAUTION:Return eye slings using oval aluminium sleeves must be properly swaged to attain strength.

Solicita tu cotizacion aqui

Aluminium Ferrules Specification EN 13411-3 (DIN3093)

H-Quality aluminum ferrules are manufactured per EN13411-3 (DIN 3093) from #1 to #60. For safety in fabrication and application, our ferrules are made of strictly material

corresponding to the requirements of EN 13411-3 (DIN 3093) regarding material composition and mechanical properties.

Solicita tu cotizacion aqui

Aluminium Ferrules JIS Type

Solicita tu cotizacion aqui

Aluminium Stop Buttons

Solicita tu cotizacion aqui

Copper Button Stops

Zinc Plated, Nickle Plated & Chrome Plated are available on request.

Solicita tu cotizacion aqui

Copper Hourglass Sleeves

Extruded copper hourglass sleeves and stop buttons have efficient cold forming properties, and are ideal for non-rusting permanent splices. These sleeves and buttons are 99% pure copper, adn the mass of copper provides excellent holding strength.

Return eye splice using copper hourglass sleeves will attain 95% of Improved Plow wire rope catalog strength when properly swaged.

CAUTION: Return eye slings using copper hourglass sleeves must be properly swaged to attain strength.

Solicita tu cotizacion aqui

Copper Ferrules

Solicita tu cotizacion aqui

Steel Stop Buttons

Specially processed low carbon steel

Solicita tu cotizacion aqui

Steel Oval Sleeves

Specially processed low carbon steel

Note: Steel Oval Sleeves are recommended for use with 6×19 or 6×37, IPS ORxIP(EIP), RRL, FC or IWRC wire rope

Solicita tu cotizacion aqui

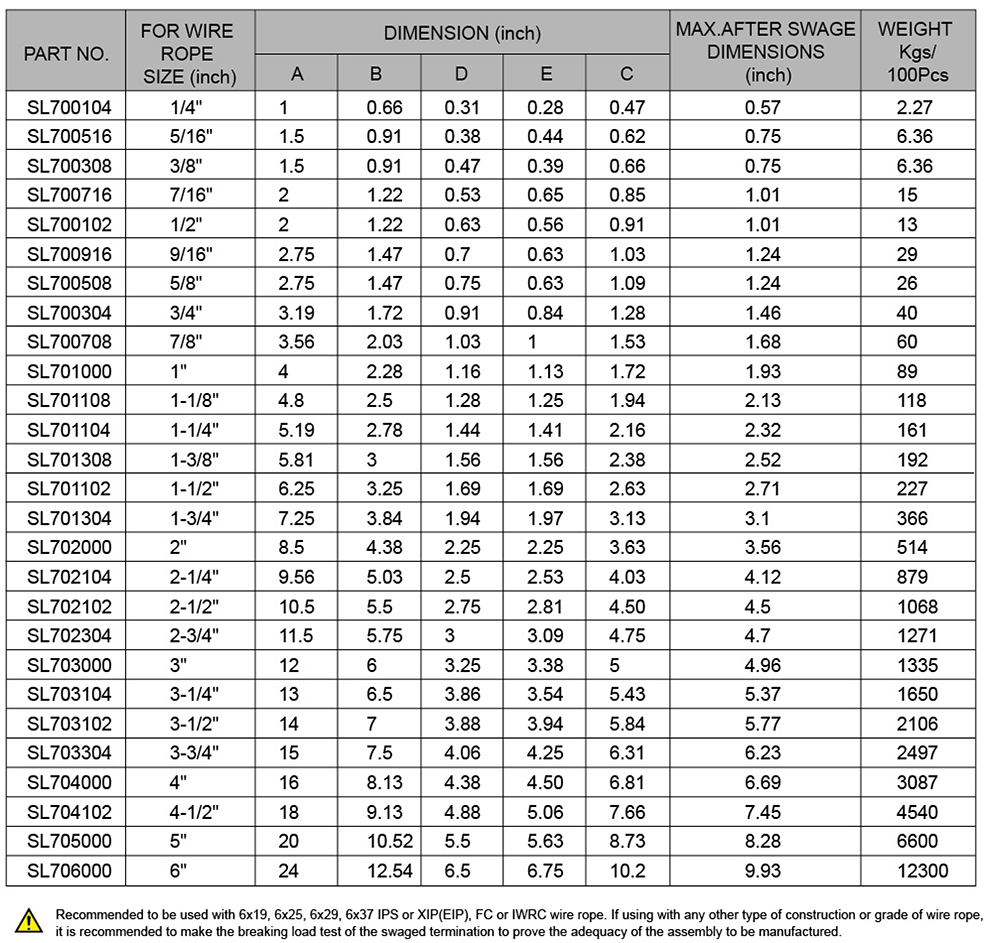

Flemish Eye Steel Swaging Sleeves (S-505)

Our modern in-house forging, heat treatment, sand blasting, auto-marding facilities assures the consistent quality of Flemish eye steel sleeves form 1/4″ to 6″ (galvanized and self-colored).

Solicita tu cotizacion aqui

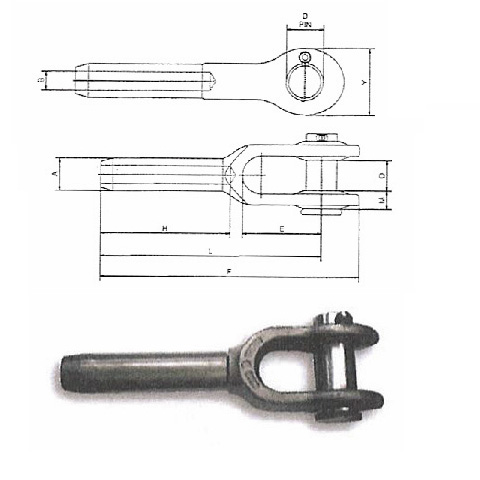

Forged open swage terminal

Wire rope terminations will not be adversely affected by temperatures between -40 ‘C-150 ‘C.

Swage terminals properly applied have an efficiency rating of more than 90% according to EN 13411-8.

Material:

Forged from special C-1035 steed, fine grain, special bar quality.

Spheroidized annealed for cold swaging.

Applicable rope type and grade:

The tested class is 8*19, fill factor 0.74, rope grade 2160.

The tested class is 6*36 (IWRC), fill factor 0.59, rope grade 2160.

Swage terminals are also recommended for use on 6*19 or 6*37 IWRC regular lay ropes.

They are not recommended for use on fibre core or lang lay ropes.

NOTE! Due to the variety of steel wire ropes, it is difficult to approve all of them. Verifying tests must be performed in order to verify the strength of the application. Steel wire rope with a fibre core has not been tested. Contact our Technical Department for more advice

Solicita tu cotizacion aqui

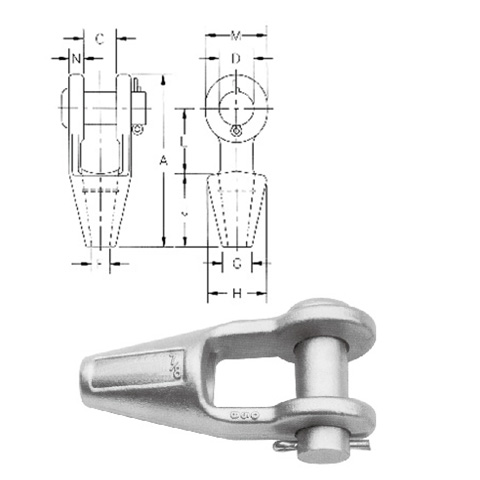

Forged closed swage terminals

Wire rope terminations will not be adversely affected by temperatures between -40″t-150·c.

Swage terminals properly applied have an efficiency rating of more than 90% according to EN 13411-8. This rating is based on the catalogue strength of the wire rope.

Material:

Forged from special C-1035 steed, fine grain, special bar quality.

Spheroidized annealed for cold swaging.

Applicable rope type and grade:

The tested class is 8*19, fill factor 0.74, rope grade 2160.

The tested class is 6*36 (IWRC), fill factor 0.59, rope grade 2160.

Swage terminals are also recommended for use on 6*19 or 6*37 IWRC regular lay ropes.

They are not recommended for use on fibre core or lang lay ropes.

NOTE! Due to the variety of steel wire ropes, it is difficult to approve all of them, Verifying tests must be performed in order to verify the strength of the application.Steel wire rope with a fibre core has not been tested. Contact our Technical Department for more advice

Solicita tu cotizacion aqui

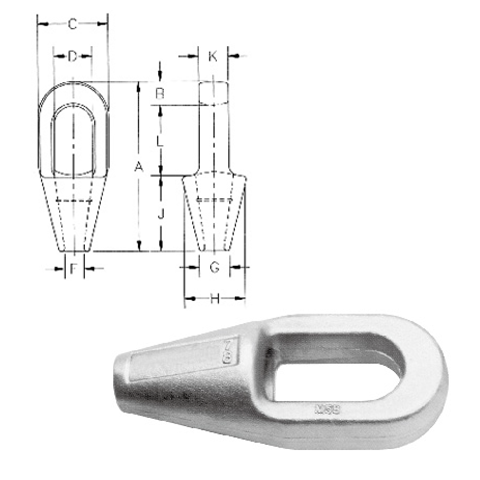

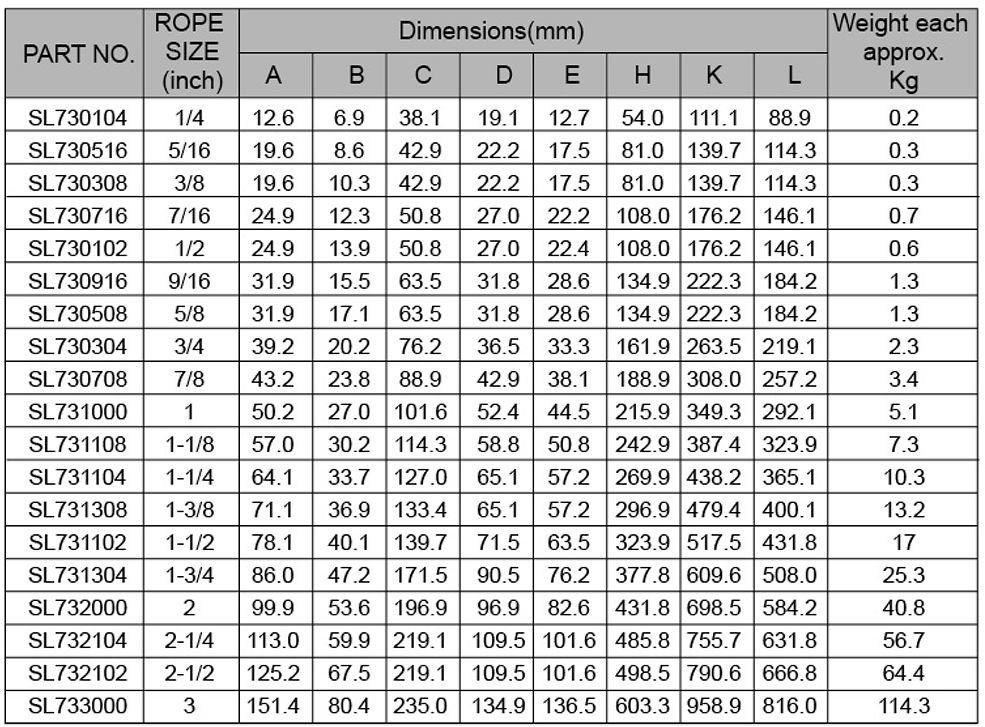

Grooved Open Spelter Sockets

Open Grooved Sockets meet the performance requirements of Federal Specification RR-S-550D, Type A, except for those provisions required of the contractor.

Note: The drawing illustrates one groove used on sockets 1/4″ thru 3/4″ Sizes 7/8″ thru 1 1/2″ use 2 grooves, Sizes 1 5/8″ and larger use 3 grooves.

* Forged Steel Sockets thru 1 1/2″ , cast alloy steel 1-5/8″ thru 4″

* Spelter socket terminations have an efficiency rating of 100%, based on the catalogue strength of wire rope.

Ratings are based on recommended use with 6×7, 6×19 or 6×37, IPS OR XIP, XXIP(EIP), RRL, FC, OR IWRC wire rope.

Solicita tu cotizacion aqui

Grooved Closed Spelter Sockets

Closed Grooved Sockets meet the performance requirements of Federal Specification RR-S-550D, Type B, except for those provisions required of the contractor.

Note: The drawing illustrates one groove used on sockets 1 /4″ thru 3/4 11 Sizes 718″ thru 1 1/2″ use 2 grooves, Sizes 1 5/8″ and larger use 3 grooves.

* Forged Steel Sockets thru 1 1 /2″ , cast alloy steel 1-5/8″ thru 4″

* Spelter socket terminations have an efficiency rating of 100%, based on the catalogue strength of wire rope.

Ratings are based on recommended use with 6×7, 6×19 or 6×37, IPS OR XIP, XXIP(EIP), RRL, FC, OR IWRC wire rope.

Solicita tu cotizacion aqui

Solicita tu cotizacion aqui

[fluentform id=”12″][hfe_template id=’240′]